Leave Your Message

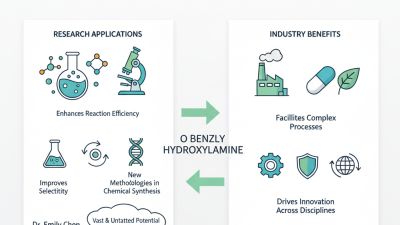

Phthalic Acid is a versatile chemical compound that has found its way into various industries due to its unique properties and applications. As a key ingredient in the production of plasticizers, it plays a crucial role in enhancing the flexibility and durability of plastics. However, the uses of Phthalic Acid extend far beyond just plastic manufacturing. This significant compound is also involved in the synthesis of dyes, resins, and other chemical intermediates that are essential in countless everyday products.

Understanding the diverse applications of Phthalic Acid can provide invaluable insights into its importance across multiple sectors. From the automotive and construction industries to consumer goods and textiles, this compound is integral to enhancing performance and longevity. Thus, exploring the top 10 uses of Phthalic Acid not only highlights its versatility but also underscores its pivotal role in modern manufacturing processes. In this article, we aim to delve into these uses, shedding light on how Phthalic Acid contributes to innovation and efficiency in a wide array of applications.

Phthalic acid is a versatile compound widely used in various industries due to its unique chemical properties. One of the primary uses of phthalic acid is in the production of plasticizers, which are essential for enhancing the flexibility and durability of plastics.

According to a report by Grand View Research, the global plasticizer market is projected to reach USD 17.89 billion by 2025, driven largely by increasing demand in the construction and automotive sectors. Phthalic acid helps to improve the performance characteristics of polyvinyl chloride (PVC) and other plastics, making it indispensable in manufacturing processes.

Another significant application of phthalic acid is in the production of alkyd resins, which are commonly used in coatings and paints. These resins provide excellent durability and gloss, making them suitable for both indoor and outdoor applications. The coatings market is expected to witness substantial growth, reaching approximately USD 187 billion by 2023, as reported by Market Research Future. This highlights the growing demand for phthalic acid in developing high-quality, long-lasting coating products.

Tips: When working with phthalic acid, it's crucial to ensure proper safety measures are in place. Always use protective equipment and work in well-ventilated areas to minimize exposure. Additionally, consider the environmental impact of phthalic acid and opt for alternatives where suitable to promote sustainability in manufacturing processes. Understanding the various applications of phthalic acid can greatly benefit industries looking to innovate and improve their product offerings.

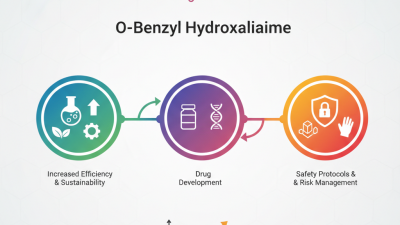

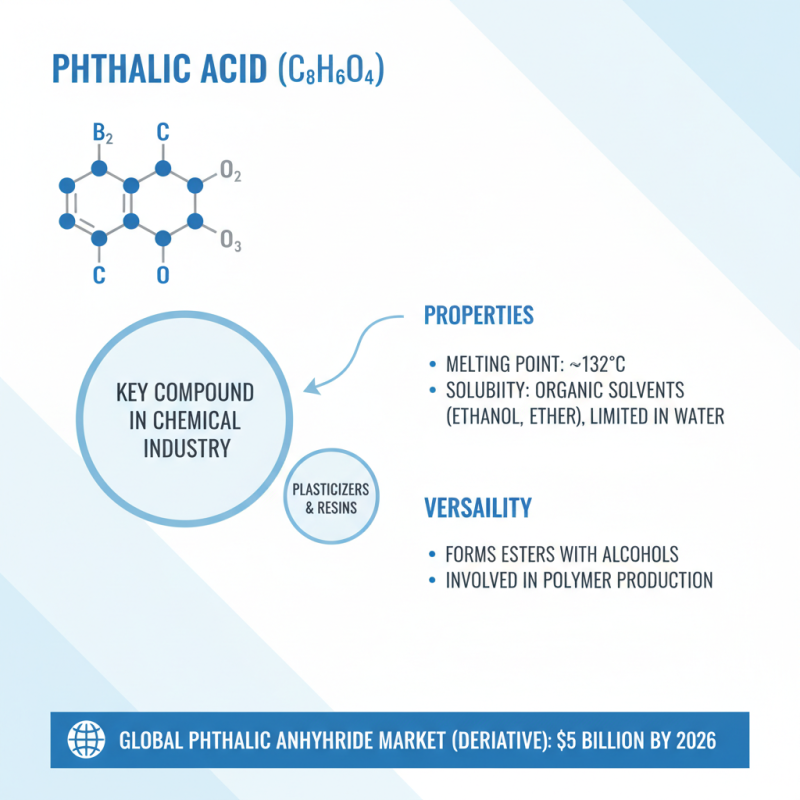

Phthalic acid, with the chemical formula C8H6O4, is a key compound in the chemical industry, particularly recognized for its role in producing plasticizers and resins. This aromatic dicarboxylic acid exhibits versatility owing to its chemical properties, such as its ability to form esters with alcohols and its involvement in the production of various polymers. Its melting point is around 132 degrees Celsius, and it is soluble in organic solvents like ethanol and ether, while exhibiting limited solubility in water. According to the International Chemical Industry Report, the global market for phthalic anhydride, a derivative of phthalic acid, is projected to reach USD 5 billion by 2026, reflecting its substantial demand in the industry.

Tips: When handling phthalic acid or its derivatives, always ensure proper ventilation and use appropriate personal protective equipment (PPE) to minimize exposure to fumes. Additionally, due to the acid's reactivity, it's crucial to store it in a cool, dry place away from incompatible substances to prevent hazardous reactions.

Phthalic acid is primarily employed in the synthesis of plasticizers, which are added to plastics to enhance flexibility and durability. It also plays a vital role in the manufacture of alkyd resins used for paints and coatings. Moreover, phthalic acid esters are widely used as intermediates in the production of dyes and pharmaceuticals. Understanding the industrial applications and chemical behavior of phthalic acid informs professionals in the field about its potential and safe usage in various chemical processes.

Phthalic acid plays a crucial role in the production of plasticizers, which are essential additives in the manufacturing of flexible plastics. These compounds enhance the properties of plastics by increasing their durability, flexibility, and workability, making them vital in a wide range of applications, from construction materials to household items. By modifying the molecular structure of polymers, phthalic acid-derived plasticizers improve the overall performance of products, allowing them to withstand various environmental conditions while maintaining their desirable characteristics.

The production process of plasticizers involves the esterification of phthalic acid with alcohols, resulting in the formation of phthalate esters. These esters not only enhance the pliability of plastics but also contribute to their resistance to degradation. This is particularly important in applications where long-lasting performance is required, such as in electrical cables, automotive interiors, and medical devices. Moreover, the versatility of phthalic acid allows for the creation of a diverse range of plasticizers, catering to different needs within the industry, thereby sustaining the demand for phthalic acid in various manufacturing sectors.

Phthalic acid plays a pivotal role in the dye and pigment industry, serving as a crucial building block for a variety of synthetic dyes. Its applications extend to both solvent-based and water-based systems, making it versatile for numerous formulations. According to a report by Grand View Research, the global market for dyes, including phthalic acid derivatives, is expected to reach USD 25.4 billion by 2025, driven by increasing demand from textiles, plastics, and coatings sectors. This trend highlights the significance of phthalic acid as an essential component in creating vibrant and durable colors.

In the manufacture of pigments, phthalic acid is particularly valued for its ability to enhance colorfastness and stability, critical properties for applications in industrial coatings and plastics. A study published in the Journal of Coatings Technology indicates that pigments formulated with phthalic acid not only exhibit improved resistance to fading and degradation but also provide a more comprehensive color spectrum. The compound serves as a plasticizer in acrylic and vinyl formulations, ensuring that the final products maintain their visual appeal over extended periods.

As regulatory standards tighten around chemical safety and environmental impact, the demand for sustainable and efficient dye solutions incorporating phthalic acid is likely to grow, reinforcing its importance in the chemical industry.

Phthalic acid plays a crucial role in the manufacturing of resins, which are essential materials used in various industrial applications. Among the most significant resins produced using phthalic acid are alkyd resins, commonly utilized in paints, coatings, and adhesives. The chemical structure of phthalic acid allows it to effectively modify the properties of these resins, enhancing their durability, flexibility, and adhesion. This modification is particularly important in applications where long-lasting and weather-resistant materials are required.

In addition to alkyd resins, phthalic acid is also used in the synthesis of unsaturated polyester resins. These resins are favored in the production of fiberglass, automotive parts, and other composite materials due to their excellent mechanical properties and chemical resistance. The incorporation of phthalic acid in the resin formulation allows for optimized curing processes, contributing to a fast and efficient production cycle. Overall, the unique characteristics of phthalic acid significantly enhance the performance and versatility of resin products across various industries, making it a vital ingredient in modern manufacturing processes.

Phthalic Acid is a versatile compound with numerous applications across various industries. It serves as a key ingredient in the production of plasticizers, which are essential for enhancing the flexibility and durability of plastics. Additionally, Phthalic Acid plays a significant role in the formulation of dyes and pigments, contributing to vibrant colors in various products. Its use extends to manufacturing resins, where it aids in creating strong, long-lasting materials.

Furthermore, Phthalic Acid is utilized in the development of agricultural chemicals and fertilizers, supporting the enhancement of crop yields. Its chemical properties make it an important component in these applications, showcasing its importance in modern manufacturing and agriculture. Understanding the diverse uses of Phthalic Acid highlights its relevance in producing everyday items and improving agricultural practices.